Vielen Dank für Ihre

Aufmerksamkeit AUF JESHENG !

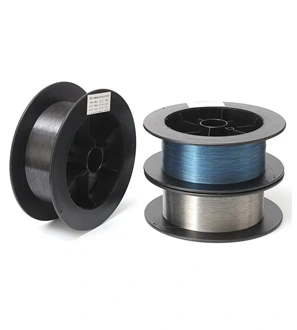

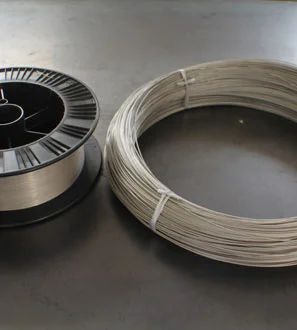

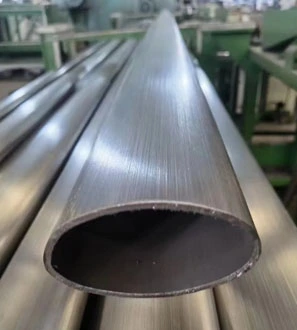

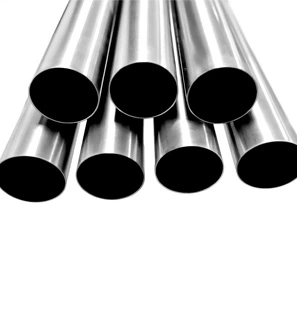

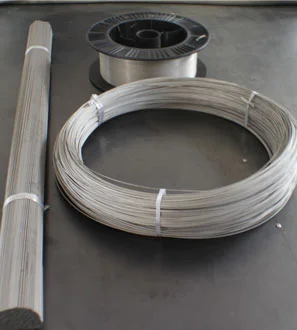

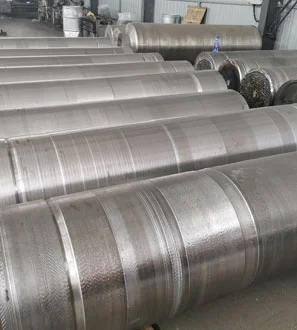

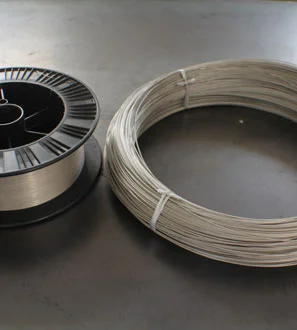

Titan-Schweiß draht Vorrat zum Verkauf

Übersicht über Titan-Schweiß draht

Yesheng Titanium Weld Wire aus reinem Titan oder Titan legierungen ist ein Premium-Schweiß draht produkt. Für die Luft-und Raumfahrt-, Medizin-, Chemie-, Schiffs-und Automobili ndustrie werden diese Schweiß drähte häufig zum Fügen verschiedener Titan teile und-komponenten verwendet. Die hohe Festigkeit, Korrosions beständigkeit und außer gewöhnliche Schweiß fähigkeit von Yesheng Titanium Weld Draht machen es zu einer beliebten Wahl. Anfrage wettbewerbs fähige Titan Schweiß draht Preis!Yeshengti ist einTitan draht lieferantFür eine benutzer definierte Auswahl klicken Sie hier für mehr.

Merkmale des Titan-Schweiß drahtes

-

1

Hohe Festigkeit: Titan-Schweiß draht hat ein sehr hohes Verhältnis von Festigkeit zu Gewicht und ist damit ein ideales Material für viele Hoch leistungs anwendungen.

-

2

Korrosions beständigkeit: Titan ist in einer Vielzahl von Umgebungen, einschl ießlich Meerwasser, Säuren und alkalischen Lösungen, sehr korrosions beständig.

-

3

Geringe Wärme ausdehnung: Titan hat einen sehr niedrigen Wärme ausdehnung koeffizienten, was zu einer aus gezeichneten Dimensions stabilität führt.

-

4

Hoher Schmelzpunkt: Titan hat einen hohen Schmelzpunkt, wodurch es für Anwendungen mit hohen Temperaturen geeignet ist.

-

5

Gute elektrische Leitfähig keit: Titan hat eine gute elektrische Leitfähig keit, was es ideal für den Einsatz in elektrischen Anwendungen macht.

-

6

Leicht gewicht: Titan ist leicht und eignet sich daher für Anwendungen, bei denen das Gewicht ein kritischer Faktor ist.

-

7

Bioko mpatibel: Titan ist bioko mpatibel und damit ideal für den Einsatz in medizinischen Implantaten.

-

8

Nicht magnetisch: Titan ist nicht magnetisch und eignet sich daher ideal für Anwendungen, bei denen Magnetfelder vermieden werden müssen.

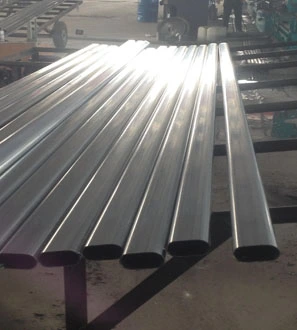

Titanium Weld Wire Specification

| Product Name | Titanium wire |

| Grade | GR1, GR2, GR5, GR5ELI, GR7, GR9, GR12, GR23, Ti-4Al-2V, Ti-4Al-1.5Mn. |

| Size | Diameter 0.02mm-5mm or as your request |

| Standard | ASTM F1341-1999, AMS4951-2003, AMS4954-2003, BS2TA28:1974, GB/T3623-2007, GJB2219-1994, ΓOCT27265-87, JISH4670-1993, DIN17863-1973 |

| Brand Name | Yesheng |

| Application | chemical industry, Aerospace, deep sea, military, medical, etc. |

| Feature | High corrosion resistance, low density, good thermal stability, High strength and light weight. |

| Technics | hot rolled and cold rolled, extruded. |

| Surface | Annealed surface, pickled surface, bright surface. |

| Packing | Export Standard Woodcase |

| MOQ | as your request |

| Payment terms | T/T, Western Union, PayPal. |

| Certificate | ISO 9001:2015; The third test report. |

| Delivery time | 10—25days according to the quantity and process of the product |

| Quality and test | Ingredient testing |

| Price Term: | CIF CNF/CFR FOB Ex-work |

Welding method of titanium welding wire

Welding titanium welding wire is a critical process that demands precision and expertise due to the unique properties of titanium alloys. Several welding methods are available for working with these materials, each with its own advantages and considerations.

Gas tungsten arc welding (GTAW), also known as TIG (tungsten inert gas) welding, is one of the most commonly used methods for welding titanium alloys. It is favored for its ability to produce high-quality welds and its versatility in achieving good results. TIG welding is known for its clean and precise welds, making it a preferred choice in aerospace, medical, and high-performance applications.

Gas metal arc welding (GMAW), or MIG (metal inert gas) welding, is another commonly used method for welding titanium. It is especially suitable for certain situations, such as when high deposition rates are required. This method offers efficiency and ease of use while ensuring strong and reliable welds.

Other methods, like resistance welding, plasma arc welding, and electron beam welding, can also be used for titanium alloys but are relatively limited in their applications.

Additionally, more advanced techniques like laser welding offer benefits in terms of speed and precision, making them suitable for specific requirements.

In summary, the welding method for titanium welding wire is carefully selected based on the specific needs of the application, taking into account factors like material thickness, joint configuration, and the desired weld quality. Each method has its unique strengths, allowing for tailored solutions in various industries, including aerospace, medical, and high-performance manufacturing.

Manufacturing quality certifications for titanium welding wire

Manufacturing quality certifications for titanium welding wire are essential to ensure the reliability and performance of this crucial material in various industries. Titanium welding wire is a vital component used in welding titanium alloys and custom titanium products, and adhering to stringent quality standards is paramount.

Certifications for titanium welding wire manufacturing typically include compliance with industry-recognized standards such as AWS A5.16. This standard specifies the requirements for titanium and titanium alloy welding wire, ensuring that it meets precise composition and quality specifications. The different grades, such as ErTi-2, ErTi-3, ErTi-5, ErTi-7, and Er-12, adhere to these standards, reflecting the specific alloy composition and characteristics suitable for distinct applications.

Quality certifications are a testament to the commitment of manufacturers to maintain consistency and precision in the production of titanium welding wire. These certifications ensure that the material meets the demands of critical industries like aerospace, medical, and high-performance manufacturing, where precision, reliability, and performance are non-negotiable.

Having the appropriate quality certifications guarantees that titanium welding wire aligns with the stringent requirements of industries, reinforcing its value as an indispensable material for welding titanium alloys, and ensuring that it delivers the expected performance and longevity in critical applications.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский